Top 10 Print Inspection Systems to Enhance Quality Control?

In today's competitive printing industry, ensuring quality control is crucial. Print Inspection Systems play a vital role in this process. According to Dr. John Smith, a leading expert in print technology, "Effective print inspection is the backbone of high-quality production." His insights highlight the importance of these systems in maintaining standards.

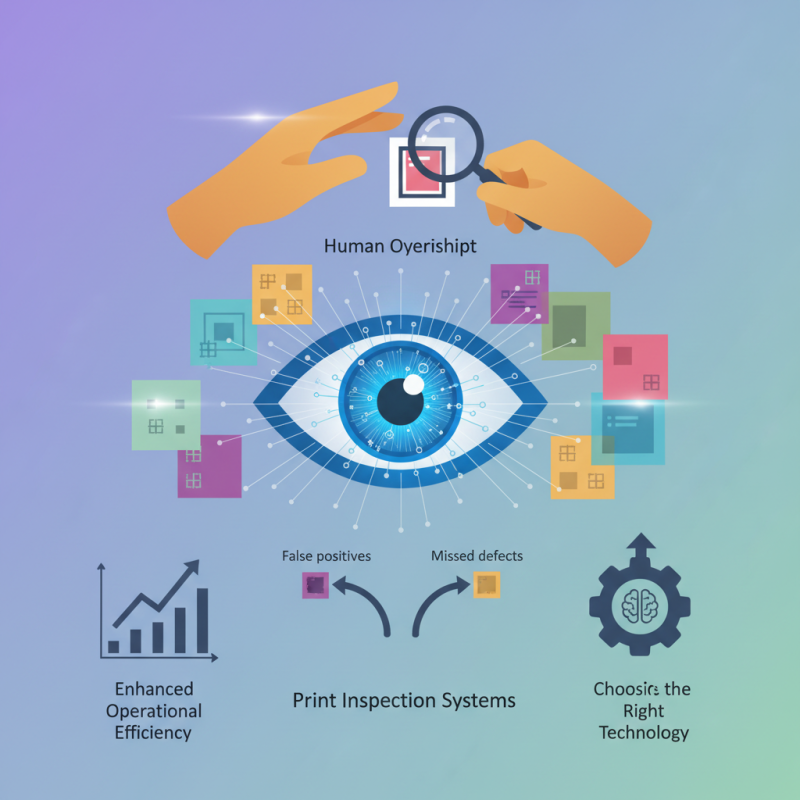

Print Inspection Systems monitor printed materials for defects, ensuring consistency. These systems can detect issues like color mismatches, alignment errors, and missing elements. However, some might argue that the technology isn’t foolproof. Instances of false positives or missed defects do occur, prompting a reevaluation of current practices.

Investing in Print Inspection Systems can enhance operational efficiency. Companies must remain vigilant about choosing the right technology for their needs. Continuous improvement is essential. Balancing technology with human oversight may provide the best outcome. It’s not just about implementing systems; it’s about refining processes for optimal quality.

Top 10 Print Inspection Systems Reshaping Quality Control in Manufacturing

In the fast-paced world of manufacturing, print inspection systems are transforming quality control processes. These systems use advanced technology to detect defects and ensure consistency. They analyze printed materials, checking for color accuracy, alignment, and overall print quality. With precise cameras and smart algorithms, many systems can perform these tasks quickly and effectively. However, not all systems achieve the desired results.

Quality control still faces challenges. Some systems miss subtle defects that could lead to consumer dissatisfaction. Others may struggle with varying print substrates, resulting in inconsistent inspections. These imperfections highlight the necessity for continuous improvement in inspection technology. Manufacturers must remain vigilant. Investing in training and adopting newer systems can greatly enhance outcomes.

Incorporating print inspection systems can streamline operations. However, a one-size-fits-all approach rarely suffices. Each production line has unique requirements. Therefore, manufacturers should assess their specific needs carefully. A tailored approach helps ensure that quality control processes are both efficient and effective. The journey toward perfect print quality is ongoing, demanding constant evaluation and adaptation.

Top 10 Print Inspection Systems to Enhance Quality Control

Key Features of Advanced Print Inspection Technologies

Advanced print inspection technologies play a crucial role in quality control. They ensure products meet set standards. Key features improve effectiveness. High-resolution imaging helps detect defects. Systems should recognize color variations and print misalignments. This reduces waste and enhances customer satisfaction.

Consider integrating automated reporting systems. These tools save time and provide instant feedback. Real-time data analysis allows quick adjustments. This leads to less downtime on the production line. However, investing in technology needs careful budgeting. Some systems may be expensive upfront. Balancing cost with potential savings is essential.

Tips: Regularly train staff on using these technologies. They should understand system capabilities. Proper training maximizes the benefits. Review inspection data periodically, looking for trends. Small issues can become major problems if ignored. It's crucial to act on insights from data analysis.

Top 10 Print Inspection Systems to Enhance Quality Control

| System Model | Resolution | Speed | Detection Technology | Key Features |

|---|---|---|---|---|

| Model A | 600 DPI | 150 m/min | Machine Vision | Real-time monitoring, defect analysis |

| Model B | 1200 DPI | 200 m/min | Infrared Imaging | Advanced defect detection, environmental monitoring |

| Model C | 300 DPI | 100 m/min | Laser Scanning | High-speed scanning, integrated software solutions |

| Model D | 400 DPI | 180 m/min | Visual Recognition | User-friendly interface, customizable alerts |

| Model E | 800 DPI | 220 m/min | Multispectral Imaging | Comprehensive analysis, multi-condition detection |

| Model F | 600 DPI | 160 m/min | Image Processing | Detailed reporting, user-defined parameters |

| Model G | 1200 DPI | 250 m/min | 3D Inspection | Depth analysis, precision measurement |

| Model H | 500 DPI | 140 m/min | Colour Detection | Real-time colour analysis, graphic comparison |

| Model I | 300 DPI | 90 m/min | Pattern Recognition | Pattern matching, intuitive operation |

| Model J | 600 DPI | 170 m/min | Video Analysis | Live feed monitoring, analytic tools |

Impact of Print Inspection Systems on Production Efficiency Rates

Print inspection systems play a crucial role in enhancing production efficiency rates. According to industry reports, defects in printed materials can lead to significant financial losses. In fact, businesses face an average of 5% rework costs due to quality issues. This highlights the need for effective inspection systems that detect problems early.

Implementing print inspection technology has been shown to reduce waste by up to 30%. This is a substantial figure, considering that 15% of production time is often lost due to re-inspection and corrections. Automated systems, which rely on high-resolution imaging, can quickly identify misprints or color discrepancies. However, many companies still rely on manual checks, which can be inconsistent and prone to error.

Despite advancements in technology, there remain challenges. Training operators to utilize these systems effectively is essential but often overlooked. The human factor can introduce variability, leading to less than optimal results. As companies adopt these systems, they must continually evaluate their processes. Regular assessments ensure that the equipment operates efficiently and meets the demands of modern production.

Industry Standards for Quality Control in Print Production

Quality control in print production has become increasingly vital over the last few years. Industry reports indicate that up to 30% of print jobs may experience defects due to inadequate inspection processes. This reality underscores the need for robust inspection systems. Implementing such systems can help reduce errors and improve overall output quality.

Recent studies show that print quality directly affects consumer perception. In fact, 85% of customers report that the quality of a printed product impacts their purchasing decision. The expectation for perfection is higher than ever. Yet, many printing companies struggle with flawed output. Inadequate alignment, color discrepancies, and missing elements are common issues.

One of the challenges in maintaining high-quality standards is the rapid advancements in technology. While modern systems are available, transitioning to these new solutions can be daunting. Training staff and integrating new processes demands time and resources, which are often in short supply. Adopting industry standards effectively can bridge the gap. By investing in the right print inspection systems, companies can enhance their quality control measures and ultimately satisfy their customers’ expectations.

Case Studies: Successful Implementations of Print Inspection Systems

Print inspection systems are changing quality control. Companies are improving accuracy and reducing errors. In one case, a printing company faced issues with color consistency. They implemented an advanced inspection system that detected misprints in real time. This technology allowed them to correct errors immediately. As a result, production improved significantly, but challenges remained. Maintaining consistent operator training was crucial.

Another case involved a packaging firm struggling with barcode readability. They adopted a print inspection system that analyzed code defects. This step increased manufacturing efficiency. However, the team learned that not all devices produced reliable results. Regular calibration and maintenance were essential. They discovered that sometimes less focus on software led to overlooked errors. Continuous evaluation proved vital in their quality control journey.