What is Enameled Aluminum Magnet Wire and its Applications?

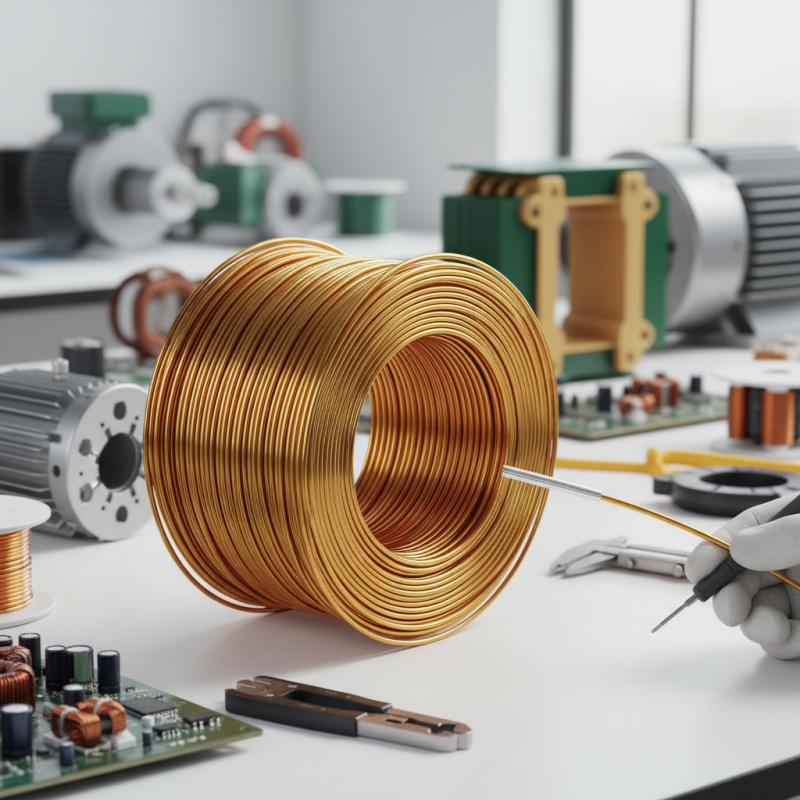

Enameled Aluminum Magnet Wire is a specialized product in the electrical industry. It consists of aluminum wire coated with an insulating enamel layer. This unique structure allows for high efficiency and durability in various applications. Industries rely on this wire for its lightweight properties and cost-effective manufacturing.

The use of Enameled Aluminum Magnet Wire extends across several sectors. From motors to transformers, its versatility is impressive. However, not every application benefits equally from its properties. There are challenges to consider, such as the potential for corrosion. Companies must weigh the benefits against these risks.

In conclusion, while Enameled Aluminum Magnet Wire holds significant advantages, it also invites scrutiny. Understanding its performance and limitations is vital for engineers and manufacturers. This wire shapes the future of electrical design, encouraging innovation while demanding attention to detail.

What is Enameled Aluminum Magnet Wire?

Enameled aluminum magnet wire is a unique type of electrical insulation. It consists of thin aluminum wire coated with a layer of enamel. This coating provides electrical insulation while maintaining excellent conductivity. The wire is lightweight, making it suitable for various applications.

Enameled aluminum magnet wire is commonly used in motors, transformers, and inductors. Its lightweight nature contributes to energy efficiency. In many cases, it serves as a viable alternative to traditional copper wire, reducing costs. However, its use comes with challenges. The enamel coating can sometimes crack or peel, leading to decreased performance. This is an important factor to consider in manufacturing.

In practice, ensuring the integrity of the enamel layer is crucial. Small flaws can lead to significant issues down the line. Manufacturers must focus on quality control. Over time, the demand for this magnet wire is growing, but so are the expectations for performance and reliability. Enameled aluminum magnet wire has potential, but it requires careful handling and continuous improvement.

Composition and Properties of Enameled Aluminum Magnet Wire

Enameled aluminum magnet wire is composed of an aluminum core coated in a thin layer of insulation. This insulation is usually made from polymers, which provide electrical resistance. The wire is lightweight and cost-effective compared to copper wire, making it a popular choice in various applications. However, aluminum's conductivity is lower than that of copper. This can impact efficiency, particularly in high-performance motors.

The properties of enameled aluminum wire include excellent thermal stability and resistance to moisture. These qualities make it suitable for use in transformers and inductors. This wire can withstand high temperatures without degrading. However, its susceptibility to oxidation must be addressed, limiting its usability in some environments. Additionally, workers may find that handling and winding enameled aluminum wire require more care due to its stiffness and brittleness compared to copper alternatives.

While enameled aluminum magnet wire has many advantages, it's essential to consider its limitations. Users may need to reflect on the specific requirements of their applications. Are they willing to compromise on conductivity for weight and cost benefits? Balancing these factors is crucial for effective use in electrical devices.

Manufacturing Process of Enameled Aluminum Magnet Wire

The manufacturing process of enameled aluminum magnet wire involves several critical steps. Initially, aluminum wire is drawn to the desired gauge. This process ensures that the wire meets specific standards for both strength and electrical conductivity. Then, the wire undergoes cleaning to remove any contaminants. This step is essential as impurities can affect the adhesion of the enamel coating.

Next, the wire is coated with an insulating enamel. This coating is typically applied through a series of processes, such as dip-coating or spray-coating. Reports indicate that around 70% of the wire's performance depends on the quality of the enamel. The thickness and uniformity of this layer are vital for longevity and efficiency. After application, the wire is cured at high temperatures, solidifying the enamel layer.

In some instances, manufacturers face challenges in achieving uniform coatings. Variability in temperature and application techniques can lead to inconsistencies. Recent industry studies suggest that optimizing these factors could improve wire performance by 15%. However, fully understanding these complexities requires ongoing research and development.

Enameled Aluminum Magnet Wire Applications

Key Applications of Enameled Aluminum Magnet Wire in Industry

Enameled aluminum magnet wire is widely used in various industrial applications. Its lightweight nature and cost-effectiveness make it a popular choice. This wire is commonly found in electric motors, transformers, and generators. It offers good resistance to wear and tear, contributing to the longevity of devices.

In the automotive sector, enameled aluminum wire plays a crucial role. It is used in electric vehicles for efficient power generation and transmission. The wire's insulation helps to prevent short circuits and maintains electrical integrity. In home appliances, such as refrigerators and washing machines, this wire enhances energy efficiency and performance.

Despite its benefits, challenges exist. The application of enameled aluminum wire requires precise attention. Issues can arise with its soldering and connection points. It's vital to ensure proper handling during manufacturing. Certain applications may struggle with heat dissipation, which can affect performance. Continual assessment of these factors is necessary to improve outcomes in various uses.

Advantages of Using Enameled Aluminum Magnet Wire Over Copper Wire

Enameled aluminum magnet wire is gaining traction in various electrical applications. This material is lighter than traditional copper wire, making it easier to handle and install. It's also more cost-effective, which presents a significant advantage in large-scale projects. Aluminum has a lower density, so it can reduce weight in systems where weight is a concern.

One of the main benefits of using enameled aluminum is its resistance to corrosion. This property ensures a longer lifespan in harsh environments. However, not all applications may favor aluminum over copper. The conductivity of copper is superior, which could be a drawback in some high-performance scenarios. Still, advancements in aluminum wire technology can improve conductivity without sacrificing many other benefits.

Another aspect worth considering is the thermal performance of enameled aluminum. It can withstand high temperatures, but the heat dissipation isn't as efficient as copper. This discrepancy may require designers to reconsider heat management strategies. It's essential to weigh these factors carefully. While aluminum has many advantages, there are areas where it could falter. Understanding the specific needs of a project helps in making the right choice.