How to Choose the Right Low Voltage Wire for Your Electrical Projects

In the realm of electrical engineering, selecting the appropriate Low Voltage Wire is crucial for the success and safety of various projects. According to a report by the National Electrical Manufacturers Association (NEMA), the low voltage wiring market is projected to grow significantly, driven by the rising demand for energy-efficient electrical systems and the increasing implementation of smart technologies in residential and commercial spaces. Choosing the right wire not only ensures compliance with safety standards but also maximizes the efficiency of the electrical infrastructure. With wires available in various gauges, insulation types, and application specifications, understanding the fundamental differences between them is essential. This article will guide you through the key considerations to help you make an informed decision when selecting Low Voltage Wire for your electrical endeavors.

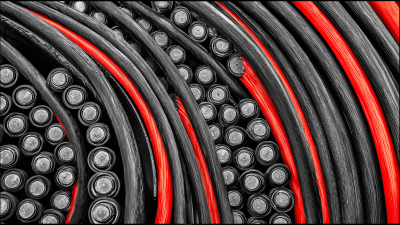

Understanding Different Types of Low Voltage Wires and Their Applications

When embarking on electrical projects, selecting the appropriate low voltage wire is crucial for ensuring safety and efficiency. Low voltage wires come in various types, each designed for specific applications. For instance, the most commonly used low voltage wire is the thermostat wire, typically employed in heating and cooling systems. It is characterized by its multiple conductors and a small gauge, allowing it to efficiently transmit signals even over long distances.

Another popular type is the landscape lighting wire, specifically designed for outdoor use. This wire features a durable sheath that protects it from environmental factors, making it ideal for connecting low voltage lighting fixtures in gardens or yards. Additionally, speaker wire is essential for audio systems, where different gauges can influence sound quality and performance. Understanding the unique properties of each low voltage wire type will empower you to make the right choice for your specific project needs.

Key Factors to Consider When Selecting Low Voltage Wire for Your Project

When selecting the right low voltage wire for your electrical projects, several key factors should be taken into account to ensure optimal performance and safety. First, consider the gauge of the wire. Thicker wires (lower gauge numbers) can carry more current, making them suitable for applications with higher power requirements. Conversely, thinner wires (higher gauge numbers) are ideal for low power applications but may experience voltage drop over longer distances. Understanding the current load and distance involved in your project will guide you in choosing the appropriate gauge.

Another crucial factor is the insulation type of the wire. Different insulation materials, such as PVC, polyethylene, and thermoplastic, offer varying degrees of heat resistance, moisture protection, and flexibility. For outdoor projects, it is essential to select wire that is rated for outdoor use to withstand environmental factors. Additionally, consider the specific application of the wire; for instance, if it will be buried underground, you might need a wire that is rated for direct burial. Thoroughly assessing these elements will help you select the right low voltage wire that meets the demands of your specific project.

Identifying Wire Gauge: How Size Affects Performance and Safety

When selecting low voltage wire for your electrical projects, understanding wire gauge is crucial as it directly affects both performance and safety. The wire gauge determines the amount of current the wire can safely carry. Thicker wires (lower gauge numbers) can handle more current than thinner wires (higher gauge numbers). Consequently, using the right gauge ensures that your electrical system operates efficiently without the risk of overheating or wire failure.

**Tips:** Always consult a wire gauge chart before purchasing wire. For most low voltage applications, a 16 or 18 gauge wire is commonly sufficient; however, if your project demands higher current, consider using a 14 gauge wire. Additionally, remember that the length of the wire run can impact performance—longer runs may require thicker wire to minimize voltage drop.

Another important factor is the insulation type of the wire. Different insulation materials, such as PVC or Teflon, provide varying levels of durability and resistance to temperature. Choosing the right insulation can enhance safety, particularly in environments where the wire may be exposed to extreme temperatures or moisture. Always check the insulation rating to ensure it aligns with your project's demands.

How to Choose the Right Low Voltage Wire for Your Electrical Projects - Identifying Wire Gauge: How Size Affects Performance and Safety

| Wire Gauge | Maximum Current (Amps) | Voltage Drop (100 ft) | Recommended Usage |

|---|---|---|---|

| 10 AWG | 30 Amps | 3.8 Volts | Heavy-duty applications, outdoor lighting |

| 12 AWG | 20 Amps | 3.1 Volts | General wiring, medium-duty applications |

| 14 AWG | 15 Amps | 2.5 Volts | Lighting circuits, standard electrical devices |

| 16 AWG | 10 Amps | 2.0 Volts | Low-current devices, small lighting |

| 18 AWG | 8 Amps | 1.6 Volts | Low power applications, headphones |

Comparing Materials: Copper vs. Aluminum for Low Voltage Wiring

When it comes to low voltage wiring, the choice of material can significantly influence both performance and cost. Copper and aluminum are the two most commonly used materials, each with its own set of advantages and disadvantages. According to the National Electrical Manufacturers Association (NEMA), copper typically offers better conductivity than aluminum, with a conductivity rate of around 97% compared to aluminum's 61%. This higher conductivity in copper allows for smaller wire gauges to achieve the same electrical carry capacity, which can be beneficial in space-constrained installations.

However, aluminum is often chosen for its lighter weight and lower cost; it is generally 50% lighter than copper and can be up to 30% cheaper. The U.S. Department of Energy notes that while aluminum can be more susceptible to oxidation and may require additional protective coatings, its use in overhead power lines is widespread due to these economic advantages. Ultimately, the decision between copper and aluminum for low voltage wiring will come down to specific project requirements, balancing factors such as budget, weight constraints, and the electrical load conditions necessary for optimal performance.

Common Mistakes to Avoid When Choosing Low Voltage Wiring for Electrical Projects

When selecting low voltage wiring for your electrical projects, avoiding common mistakes can save you time and resources. One prevalent error is underestimating the wire gauge. Using a wire that is too thin can lead to overheating and voltage drop, compromising the performance of your entire system. It's crucial to refer to the specifications of your devices and select a wire gauge that can handle the required current without exceeding its limits.

Another mistake is failing to consider the environment in which the wiring will be installed. Factors like moisture, temperature, and exposure to sunlight can significantly impact the longevity of your wiring. Choosing the wrong insulation type can result in premature deterioration. Always opt for cables rated for the specific conditions they will face, ensuring durability and safety in your installations. Taking these considerations into account will help you make informed choices and enhance the reliability of your electrical projects.

Related Posts

-

China's Excellence in Best Low Voltage Cable Manufacturing Leading Export Powerhouse

-

Choosing the Right Manufacturer for the Best Electric Cord Solutions That Meet Industry Standards

-

China's Commitment to Quality in the Global Marine Cable Market

-

Exploring Innovative Alternatives to Extension Cord Wire for Enhanced Electrical Solutions

-

Global Reach of Chinese Technology through Best Power Extension Quality Solutions

-

Top Tips for Choosing the Best Welding Cable for Your Projects